Superior Technology

Superior water treatment technology

Superior follows a precise formula based on water flow rate and pipe diameter.

Adhering to this formula ensures that the correct model of Superior Water Conditioner is selected for the designed flow rate of the application, producing optimum results consistently—a proven formula of system integration—the Superior way.

- Cost-effective water treatment

- Energy savings

- Water conservation

- Pollution prevention

Magnetic Treatment of Water

The Superior Water Conditioner controls scale and corrosion without the use of chemicals.

When water is subjected to temperature change (delta T), pressure change (delta P), friction, turbulence and/or evaporation, dissolved minerals, primarily calcium carbonate (CaCO3) and magnesium carbonate (MgCO3), will precipitate out of solution and deposit on the heat transfer surfaces of plumbing systems and equipment in the form of a rock-like build-up, commonly called lime/scale. At the molecular level, the negatively and positively charged ions of these minerals are attracted to, and bond tightly together with, one another, thus forming the lime/scale deposit known as calcite. These mineral deposits are a great insulator and require much more energy to heat or cool water in many different types of residential, commercial, institutional and industrial applications.

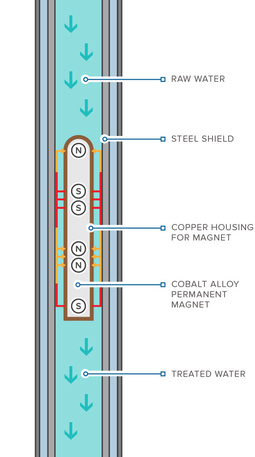

As water passes through the Superior Water Conditioner’s treatment chamber, it is subjected to a series of alternating, reversing-polarity, permanent magnetic fields, which interrupts the natural scale-forming characteristics of CaCO3 and MgCO3 by temporarily altering their ionic charge identity. Instead of being attracted to one another, the molecules are caused to act like ions of similar charges and repel one another as they precipitate out of solution. This causes the minerals to precipitate out of solution in a physical state of suspension known as aragonite (an amorphous mud-like or powdery form), rather than the hard rock-like calcite. This aragonite will flow right on through a plumbing system or drop to a low area within equipment so that it can be easily blown down or bled off. It can also be removed by other physical means such as centrifugal separation and filtration equipment. Since chemicals are unnecessary with the application of the Superior Water Conditioner, the purity of the water is not affected in any way, and it can be safely and legally discharged to a sanitary sewer or even to the environment, where allowed.

The presence of aragonite in the water provides an additional benefit in terms of corrosion protection. A thin film of the soft aragonite will adhere to all wetted surfaces of the plumbing system and equipment, keeping free oxygen and other corrosive properties in the water from reaching and attacking the metallic components, thus assisting in corrosion control.

A research project (RP-1155), sponsored by ASHRAE (American Society of Heating, Refrigeration and Air Conditioning Engineers) clearly demonstrates the benefits and efficiency of physical water treatment in controlling calcium scale accumulation in circulating, open-loop cooling water systems, and showed an 8% reduction in the water’s surface tension. The report also concluded that best results were obtained when alternating, reversing-polarity, permanent magnetic fields were used in the circulating line of the cooling tower and that mineral fouling can be substantially reduced in heat transfer equipment (chiller/condenser) applications, with significant energy and water savings.

To order this complete report by Dr. Young I. Cho with Drexel University from ASHRAE’s online bookstore, Click Here.

To order Dr. Cho’s White Paper presentation, which summarizes the affirmative conclusions of his research, to ASHRAE’s TC-3.6 Handbook Sub-Committee, Click Here.

How Superior Water Conditioners work

To order this complete report by Dr. Young I. Cho with Drexel University from ASHRAE’s online bookstore, Click Here.

To order Dr. Cho’s White Paper presentation, which summarizes the affirmative conclusions of his research, to ASHRAE’s TC-3.6 Handbook Sub-Committee, Click Here.

Further reading on this topic is available from the following sources and others

[You will need the Adobe Reader (free download) or its plug-in for your browser is required to view the following reports in Acrobat format.]

- Quinn C. J., Sanderson C. W, Molden, T.C, “Magnetic treatment of water prevents mineral build-up,” published in 8/97 Iron and Steel Engineer Magnetic Treatment of Water

- DOE Research, “Non-Chemical Technologies for Scale and Hardness Control”, DOE Report DOE/EE-0162, 1998

Advantages

There are four major concerns for all users of water with the purpose of thermal transfer:

- COST-EFFECTIVE WATER TREATMENT

- ENERGY SAVINGS

- WATER CONSERVATION

- POLLUTION PREVENTION

The Superior Water Conditioner® meets all four of these concerns for effective water treatment through control of lime/scale for thermal transfer efficiency.

The effect of thermal transfer efficiency on energy costs is well documented and represented by the chart below. (data from the University of Illinois and NIST)

The Battelle Report titled “Non-Chemical Technologies for Scale and Hardness Control,” sponsored by the Department of Energy and published in 1998, confirms that the elimination of chemicals is only part of the savings realized by the non-chemical process. An estimated calculation indicates a payback of less than one year and an adjusted internal rate return greater than 50%. Non-chemical water treatment technologies were judged life-cycle cost-effective (at one or more Federal sites) in terms of installation cost, net present value and energy savings.

Non-chemical water treatment can reduce possible costs associated with chemical water treatment:

- Transportation, storage, installation and disposal of 55-gallon drums

- Maintenance and energy for chemical feed pumps

- Maintenance for conductivity meter and solenoid valve

- Water testing materials and labor

- Heat transfer loss due to scale

- Corrosion of equipment

- Acidizing

- Labor for reporting (new laws requiring monthly reports on hazardous materials stored, used and disposed of)

- Bleeding water to control TDS

Using magnetic water treatment reduces pollution, health risks and equipment damage by eliminating the need for acidizing steam boilers and chillers to remove excessive scale that can remain despite chemical treatment.

Blow-down of the boilers and bleed-off for cooling towers can be reduced considerably after installing a properly sized and designed magnetic water conditioner. However, it may be helpful to maintain the same blow-down as before until all the scale is removed if the boiler or chiller is badly scaled at the time of installation.

Superior Water Conditioner’s® numerous benefits and absence of ill side effects merit consideration of these products. The Superior Water Conditioner® system has proven time and time again that it will pay for itself by the elimination of chemical costs alone. Payback is accelerated when all of the aforementioned costs are factored into the analysis!

| EQUIPMENT | USE | *AVERAGE PAYBACK |

|---|---|---|

| Boiler | Process Steam | 6 – 9 months |

| Boiler | Process hot water | 8 – 12 months |

| Boiler | Steam heating | 15 – 18 months |

| Boiler | Hot water heating | 24 – 36 months |

| Cooling tower | Process | 10 – 12 months |

| Cooling tower | Comfort air | **1 – 2 seasons |

*This payback varies considerably due to the quality of the water, once-through or returned-as-condensate recirculating systems, as well as the effectiveness and cost of the previous chemical treatment.

**Depends on months of year used.

Less tangible advantages of Superior Water treatment technology include:

- True pollution prevention (up front—not at the end of the pipe)

- Reduction of injury and cost (no hazardous chemicals or waste)

- Better corrosion control (outperforms other corrosion inhibitors)

The Superior Water Conditioner® technology will help industry meet the environmental requirements of EPA, DNR, DOE and other state and federal regulatory agencies.